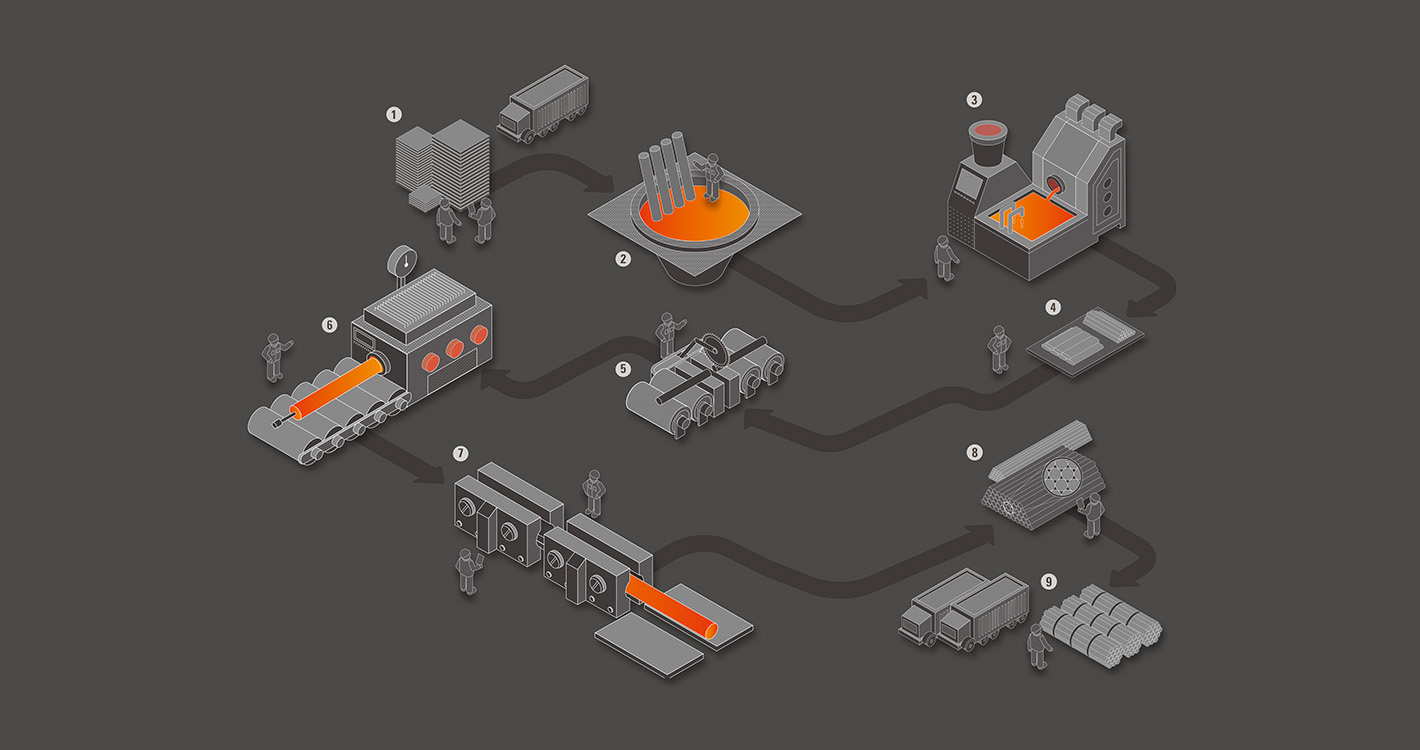

Our Business

One Alloy manufactures a variety of copper and copper alloy products using casting and extrusion technologies.

Process

-

- Raw Material Receipt and Inspection

-

We inspect the composition and quality of

raw materials before pressing.

-

- Blending and Melting

-

We blend and melt the received

raw materials and scrap metals.

-

- Casting Billets and Slabs

-

We pour and cool the molten metal into molds, casting them into billets and slabs.

-

- Inspection of Cast Products

-

We conduct composition and surface

inspections of the cast billets and slabs.

-

- Cutting

-

We cut the billets and slabs

to the required specifications.

-

- Heating

-

We heat the billets and slabs to the precise temperatures for each alloy type.

-

- Extrusion and Processing

-

We manufacture pipes and bars using

a 4,000-ton extrusion press.

-

- Quality Inspection

-

We inspect the weight, length, mass,

eccentricity, composition, and appearance.

-

- Packaging and Shipping

-

We triple-check our finished products,

deem them fit, and then ship them.